Optical brightener OB (C.I.: 184 CAS NO: 7128-64-5) is an efficient and popular whitening agent for plastics and synthetic fibers. It occurs as a milky white or light yellow crystalline powder. It can be added to monomers or prepolymers during the production of plastics and synthetic fibers, or used in the form of powder or granules (masterbatch) before or during molding. This whitening agent can significantly improve the whiteness and brightness of plastics and synthetic fibers, giving them better appearance and market competitiveness.

Product application:

1. Plastic

- PVC (polyvinyl chloride): Optical brightener OB can be used to enhance the whiteness of hard and soft PVC. The recommended dosage for whitening is 0.01-0.05% (10-50g per 100kg of material). If you need to improve transparency, the dosage is 0.0001-0.001% (0.1-1g per 100kg of material).

- PS (polystyrene): In PS, the dosage for whitening is 0.001% (1g per 100kg of material), and the dosage for improving transparency is 0.0001-0.001% (0.1-1g for every 100kg of material).

- ABS (acrylonitrile-butadiene-styrene copolymer): Adding 0.01-0.05% optical brightener OB to ABS can effectively remove the original yellow tone and achieve a whitening effect.

- Polyolefins (PE and PP): Optical brightener OB has a good whitening effect in polyethylene and polypropylene. The transparent dosage is 0.0005-0.001% (i.e. 0.5-1g added per 100kg of material), and the whitening dosage is 0.005-0.05% (i.e. 5-50g added per 100kg of material).

2. Coatings and inks

- Optical brightener OB is also suitable for use in varnishes, paints, white enamels, coatings and inks to increase brightness and provide visually attractive surfaces.

3. Synthetic fibers

- In the whitening process of synthetic fibers, the optical brightener OB has a significant effect and can significantly improve the aesthetics of the final product.

Product advantages:

1. Heat resistance

- Stable performance: Optical brightener OB retains its efficacy at higher processing temperatures, making it ideal for thermoplastic processing.

- Durability: It can withstand the heat generated during the production of various plastic products, ensuring a long-lasting whitening effect.

2. Weather resistance

- Non-Yellowing: Optical Brightener OB will not yellow over time, even when exposed to outdoor conditions.

- UV Stability: It has reliable UV resistance, maintaining the brightness and color integrity of the material.

3. Wide range of applications

- Suitable for a variety of materials: Optical brightener OB can be used on a variety of plastics and synthetic fibers, including PVC, PS, PE, PP and ABS.

- Various forms: Optical brightener OB can be added to the material in the form of powder or granules, making it more flexible.

Product features

1. Good whitening effect

- High efficiency: Fluorescent whitening agent OB has high efficiency and only needs a small amount of addition to achieve significant whitening effects, ensuring cost-effective use.

- Improved aesthetics: The whitening effect enhances the visual appeal of plastics and fibers, making products more attractive and popular with consumers.

2. Easy to use

- Easy to incorporate: Optical brightener OB can be easily added to the polymer, either before or during processing, allowing for seamless integration into existing manufacturing processes.

- Flexible dosage control: Provides a variety of dosage options according to different materials and desired effects, making applications more diverse.

3. Good light resistance

- Persistence: Fluorescent whitening agent OB ensures that the whitening effect remains stable under long-term exposure to light, extending the service life of the product.

- Color Consistency: Helps maintain uniform whiteness between products, ensuring consistent quality and appearance.

Product reference dosage:

In the production process of plastic products, in order to achieve the ideal color and transparency, an appropriate amount of additives needs to be added. The following are reference dosages for several common plastic materials:

1. PVC (polyvinyl chloride )

- Whitening: 0.01-0.05% (add 10-50g per 100kg of raw materials)

- Transparency: 0.0001-0.001% (add 0.1-1g per 100kg of raw materials)

2. PS (polystyrene)

- Whitening: 0.001% (add 1g per 100kg of raw materials)

- Transparency: 0.0001-0.001% (add 0.1-1g per 100kg of raw materials)

3. ABS (acrylonitrile-butadiene-styrene copolymer)

- Whitening: 0.01-0.05% (add 10-50g per 100kg of raw materials)

4. Polyolefins (PE and PP)

- Whitening: 0.005-0.05% (add 5-50g per 100kg of raw materials)

- Transparency: 0.0005-0.001% (add 0.5-1g per 100kg of raw materials)

EN

EN 中文

中文 ES

ES

.jpg)

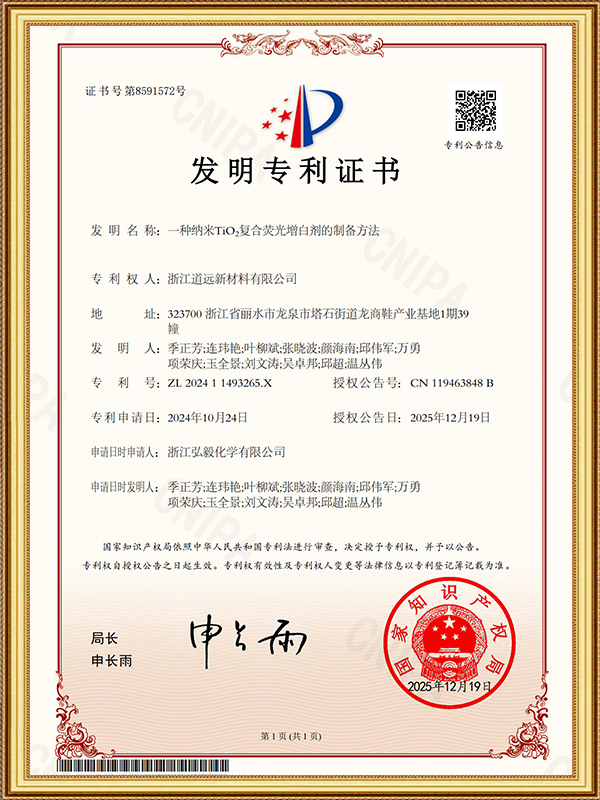

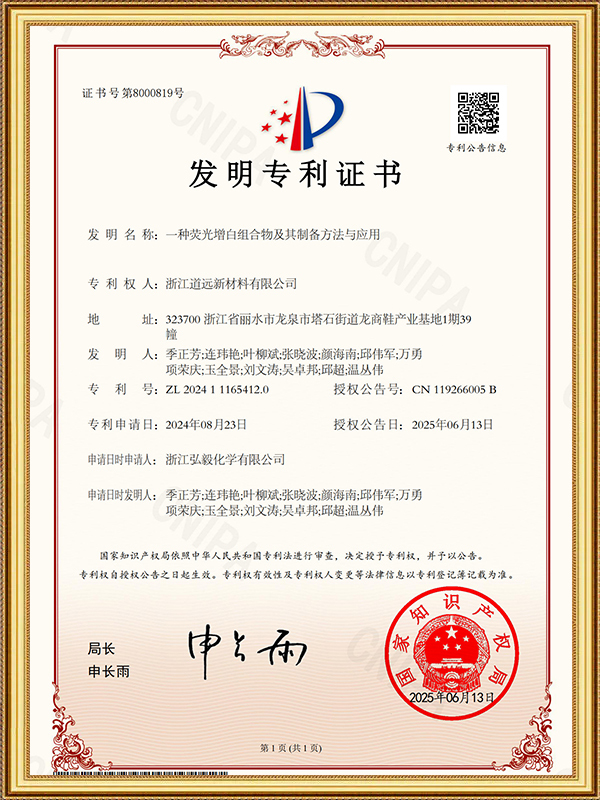

high-tech enterprise and

high-tech enterprise and